Overview

In the last two issues of The Concrete Floor Report, we presented articles that covered why cracks form in a concrete floor and how to repair them. This article is the last of the three-part series, covering repairs of surface damage in concrete floors.As discussed in the previous article, the repair process is not simply cleaning out the damaged area and troweling something in to fill the hole. The repair process requires a wide range of tools, materials, and expertise of methodologies to properly complete a repair that will last. There are several steps that are part of the repair process. Properly completing each step is critical in creating a repair that will handle the traffic and environmental conditions that the floor will be subjected to.

Evaluation Step

The first step in the repair process has several elements. The first element is an evaluation of the floor usage and investigation of the cause(s) of the damage to the concrete surface. Fortunately, in most cases, the cause of the damage to the floor is known. This is important so you can plan a specific repair without fear of reoccurrence. Obviously, a floor that is in a chemical production plant that may be exposed to harsh chemicals is going to demand a different repair than a floor in a warehouse subjected to only forklift traffic.The second element in this step is to determine if the material in and around the hole is physically sound. This will dictate how extensive the repair preparation step will have to be.

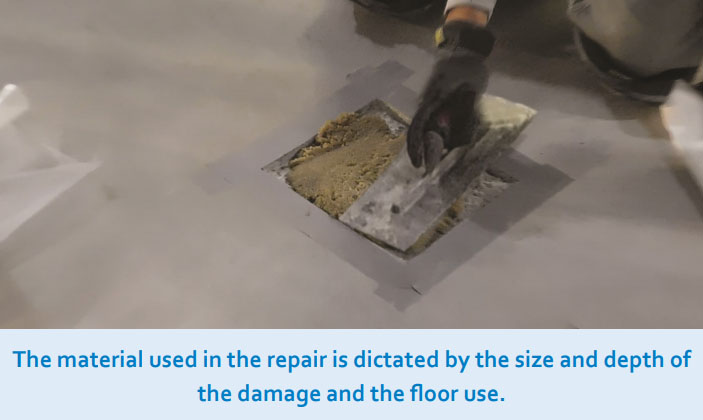

The last element is to determine what material is best for the repair considering the size and depth of the repair and the conditions the floor will be subjected to. After this, the next step in the process is preparation of the damaged area.

Preparation Step

There are two components in this step. If the surface in and around the damaged area was found not to be sound, it must be cut back enough so that the concrete in and around the damaged area is physically sound.

In addition, the preparation process must ensure that the surface in the damaged area has the proper profile or surface texture to provide a good bond between the existing concrete and the repair material.

Installation Step

The next step is to fill the damaged area with the material that was decided on during the evaluation process — and, as much as possible, match the finish of the rest of the floor.There are a wide range of products that can be used for a repair. Examples of the type of materials used would include cement based mortars, structural polyurea polymers, and structural epoxy mortars.

Finishing Step

The final step in the process is to make sure the repaired area is flush with the surrounding surface. This leads to an important comment about concrete floor repairs.

A Word About Matching

We often have customers request that concrete repairs blend in with the existing floor and are not noticeable. There have been a lot of new developments in terms of the types of material used, the blending of materials, and the ability to color repair materials. Even with all of these advances in technology, it’s unlikely that a repair is going to blend into the floor perfectly. The wide range of colors of concrete floors and the difficulty of blending an exact color makes it nearly impossible to match the color of the concrete surrounding the repair.As you have seen, repairing a damaged floor is not just filling the void created. A thoughtful, measured approach by a contractor with the expertise and experience necessary to complete the repair is the only way to get a result that will last long term.

Need Help With Your Concrete?

If you have any questions about the treatment, repair, or renovation of your concrete floor, give us a call at 716-831-7091 or email us at info@themjacompany.com.*Images courtesy of Metzger/McGuire Co.