Control Joints & Saw Cut Filling

Since all concrete floors are subject to cracking, Control Joints (or contraction joints) should be placed in fresh concrete to create weakened planes that control the severity and pattern of cracks.

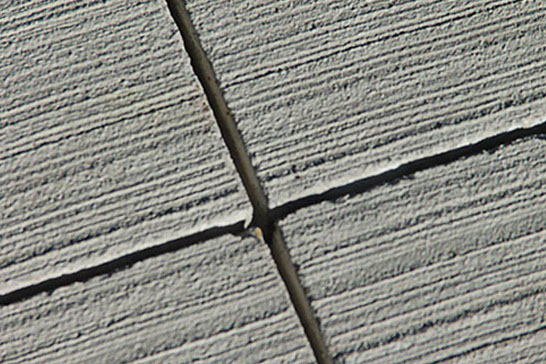

In some cases, control joints are done after the concrete has cured and hardened by cutting lines in the floors with a concrete saw. To be effective, saw cuts should be 1/4 of the slab thickness.

While these joints are important to the structural integrity of the floor, they also have the potential for damage, performance, and safety problems.

Here’s the problem and the cure for control joints:

Since control joints and saw cuts are really intentional weakening of the concrete surface, inherent problems can arise.

Control Joints:

Control joints that are placed at the time the concrete is installed and before the concrete cures are not as much of a problem as saw cuts that are done after the concrete has cured. In most cases, control joints that are created at the time of floor installation, have relatively smooth and rounded edges, so damage from impact is minimized.

However, even control joints can accumulate moisture, debris, chemicals, and be subject to increased impact. To prevent these problems, control joints can be filled to prevent contamination and create a smooth surface with is less vulnerable to wear and tear.

The MJA Company will inspect your control joints and recommend the appropriate fillers for your floor. Epoxies, polyeureas, and other products are available and should be matched to the floor and its usage.

Saw Cuts:

Saw cuts present more potential for floor damage than control joints because they are penetrating cuts at a 90-degree angle to the floor. Sharp edges are prone to chipping and cracking, especially on floors that are subject to abrasion and impact from forklifts and heavy equipment.

In the case of saw cuts, another problem is created when the top, smooth layer of the floor (Near-Surface Wear Zone) is removed. Your floor’s structural integrity can be compromised, allowing the aggregates below the surface to move and weaken.

Saw cuts are also more vulnerable to contamination since they are deeper than control joints and lack any protective layer. Water penetration is more likely with saw cuts that with conventional control joints and may create freeze-thaw cracking of the floor in areas that are subject to cold weather.

As with control joints, The MJA Company will inspect saw cuts to determine the best course of action. Chips and cracks will be repaired at the same time as the appropriate fillers are installed on the floor.